GPS Rig Acceptance Surveys

are defined as comprehensive assessments by way of a detailed evaluation of equipment and systems. This inspection will cover an in-depth survey of the state of maintenance of the rig. It includes an inspection of all safety critical elements of the installation and all equipment that could be anticipated to cause operational downtime when a mechanical failure of that equipment occurs.

The inspection includes, but is not limited to, the opening of critical equipment for verification that the equipment has been kept in a safe and reliable working condition and includes all major items of equipment to ensure a detailed examination of gear teeth, bearings, chains and ancillary parts for excessive wear, damage, cracks and other defects and for the measurements of clearances.

In addition function testing, pressure testing, load testing and insulation resistance checks for all critical equipment on board the drilling unit, as applicable, will be conducted accompanied by a check that the proper safety devices are installed and are working correctly to prevent accidents and equipment failures.

Our safety inspections can be tailored to your requirements and can incorporate IMO Modu Code, requirements, UK & reciprocal International Department of Energy standards, General Safety Equipment inspections, Safety and Emergency Procedures, Safety Cases, System and Equipment Design with relation to safety, Testing of Equipment Safety Devices and Systems as well as a review of the Safety Aspects of Well Control Equipment and Procedures.

The analysis of equipment condition and standards of maintenance is always in accordance with API & IADC standards and includes the equipment manufacturer's specifications and recommendations.

Rig Acceptance Surveys

Applying the same parameters as used in our Rig Condition Surveys, then augmenting them with specific operational testing and integrity verification, we ensure the rig, its equipment (or certain defined equipment) and systems comply to all current and applicable International industry standards.

TYPICAL WORKSCOPES INCLUDE ALL THE PARAMETERS OF OUR RIG CONDITION SURVEY WITH DETAILED EMPHASIS ON:

* Function testing, pressure testing, load testing and insulation resistance checks for all critical equipment (pressure lines included) of the unit.

* Structural inspection as well as Drilling string and Bottom Hole Assembly inspections are carried out only visually unless agreed upon by the parties.

* Verification of compliance with ISO/API International Standards, Oilfield good practices and other recognised international code of practice.

* Verification of compliance with OPERATORS minimum acceptance standard (i.e. Well Control Policy, BOP and Tubular requirements) and technical Rig Contract specifications (Personnel qualification requirements included).

The scope of the inspection will include:

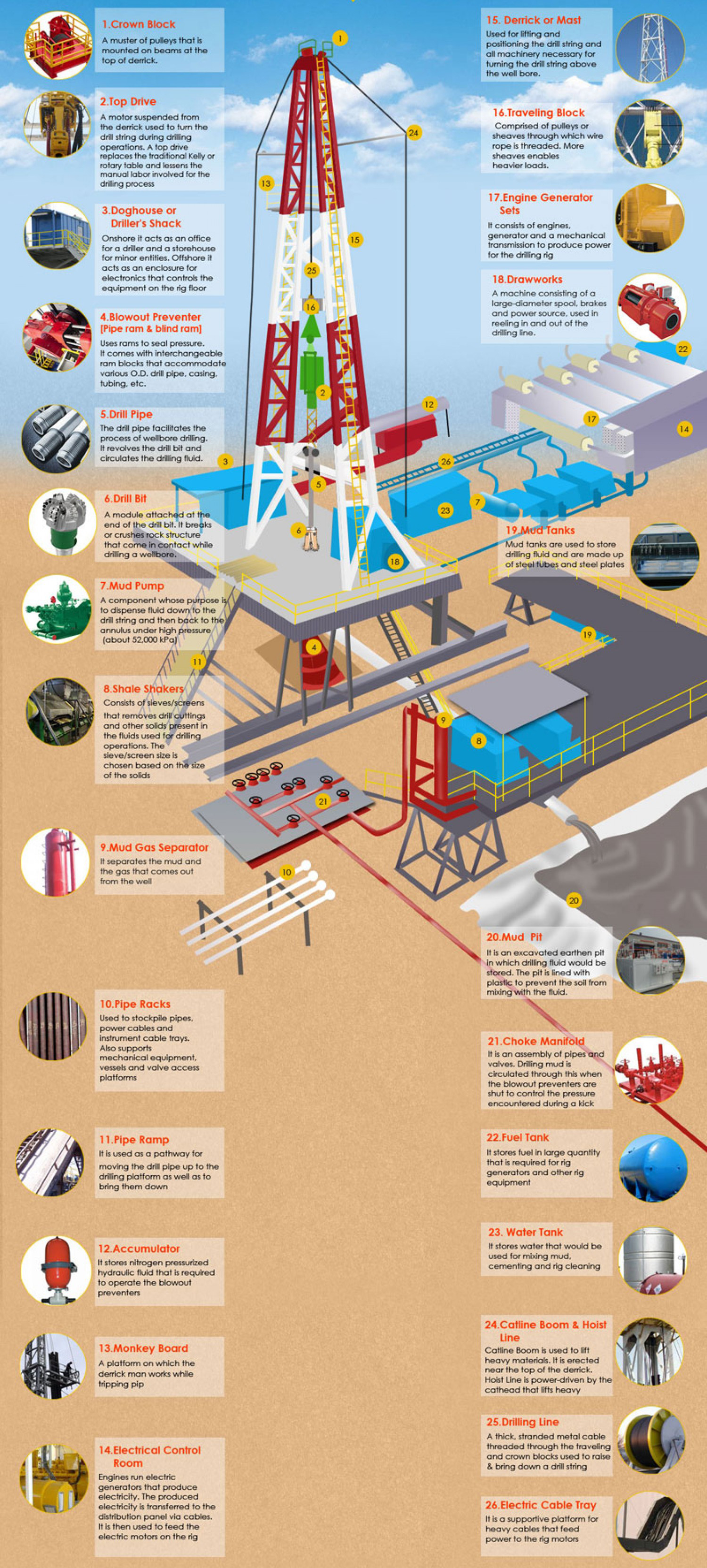

| Drilling Equipment | ||

|---|---|---|

| Draw Works and Rotary Table | Tuggers and Sheaves | Well Testing Equipment |

| Top Drive System | Man-Riding Winches | Mud Pumps and Mud Agitators |

| Swivel and Kelly Equipment | Survey Line and Ezy-Torq | Centrifugal Pumps |

| Crown Block and Travelling Block | Pipe Spinning Wrench | Shale Shaker and Mud Cleaner |

| Hook and Drill String Compensator | Pipe Handling Equipment | Desilter, Desander and Degasser |

| Drilling Instrumentation | Pipe Racker | Mud Mixing System |

| Derrick/Casing Stabbing Board | Iron Roughneck | Standpipe Manifold |

| Well Control Equipment | |

|---|---|

| Wellhead Connector | Marine Riser Joint (Pins/Boxes) |

| Ram Type BOP | Marine Riser Handling Tools |

| Annular BOP | Diverter Assembly |

| Flex Joint | Diverter Control Console |

| Marine Riser Adapter | Riser Tensioner |

| Choke and Kill Stabs | Guideline Tensioning System |

| Gate Valve, Failsafe | Underwater TV System |

| Surface Hydraulic BOP Control Unit | Choke and Kill Manifold |

| BOP Control System | Choke Remote Control Panel |

| Marine Riser System | BOP Handling Equipment |

| Electrical Equipment | |

|---|---|

| Elmagco Brake | AC Motors |

| Transformers | Generators |

| DC Motors | Electrical Safety Regulations |

| Barge Equipment | |

| Ballast and Bilge System | Bulk Air System and Tanks |

| Overflow and Vent Checks | Registration and Classification |

| Watertight Integrity | Communication Equipment |

| Mooring System | General Operations |

| Engine-Room | |

| Diesel Engines | Crane and Power System |

| Emergency Generator Set | Marine Reduction Gearbox and Propulsion |

| Watermaker | Thruster Unit |

| Air Compressor | Preventive Maintenance System |

| Safety Equipment | |

|---|---|

| Fire Control System | General Safety Items |

| Automatic Fire Detection System | Gas Detection System |

| CO2 System For Fire Control | Helicopter Facilities |

| Fire Station | Drilling Facilities Safety |

| Extinguishers & Fire-Fighting Equipment | First-Aid and Sick-Bay |

| Foam System For Heli-Deck | Emergency Procedures |

| Survival and Life-Saving | Lifting and Handling |

| Lifeboat | Living Quarters |

| Davit-Launched Life-Raft Station | Pollution Control |

| Escape Routes | Housekeeping |

| Breathing Apparatus | Work Permits |