Phased Array Ultrasonic Technology

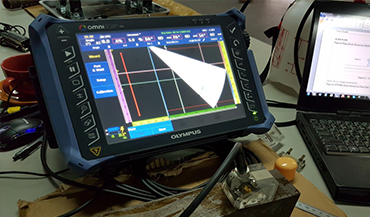

Phased Array is the latest advanced Ultrasonic technology that operates by a computer controlled excitation of individual elements in a multi-element transducer. In short, Phased Array generates multiple ultrasonic signals, in nanoseconds, that produce controllable angles, focus depths and/or wide coverage from one inspection point.

It has many advantages including

excellent repeatability, increased inspection speeds, more accurate results and the ability inspection speeds, more accurate results and the ability to inspect complex geometries.

interactive analysis of A-scans, B-scans,S-scans, and C-scans for multigroup and multiprobe inspections.

The technology also produces multiple measurements that are synchronized and cursor/ gate associated, making the detection, location and characterization of defects much more reliable and exact than the results obtained with conventional shear wave inspection.

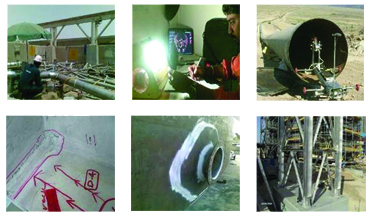

applications across a variety of industries including:

• Weld Inspection of pressure vessels piping and tubing

• Vessels and piping fabricated with composite materials

• Pressure vessel and piping welds

• Erosion/corrosion mapping.

• Corrosion mapping

• Turbine blades and Christmas tree designs

Phased arrays offer significant advantages over traditional radiography of welds as well:

• No safety hazards

• Inspection as soon as weld is cool

• Better defect detection and sizing

• Able to penetrate thick sections

• Compliant with all known codes

Time of Flight Diffraction (TOFD)

Our highly qualified automated ultrasonic engineers/technicians operate the system in both manual and automated scanning modes. automated pipe and vessel weld inspection or erosion corrosion surveys.

phased Array generates an ultrasonic beam with the capability of setting beam parameters such as angle, focal distance, and focal point size through computer controlled excitation of the beam. it can be multiplexed covering large areas and the operator can vary the angle of the beam without moving the probe. Applications include weld inspection, complex geometries, defect detection and location, and sizing. the ability to record weld scans and to visualize the reflectors and their position within the weld makes it a qualified technology and an excellent choice for projects constructed to All ASME phased array code cases , ASTM E2700-09 ASTM E2491-06, AWS, API 1104 and API RP2X,CEN EN 583-6

, BSI BS7706 And more

phased Array generates an ultrasonic beam with the capability of setting beam parameters such as angle, focal distance, and focal point size through computer controlled excitation of the beam. it can be multiplexed covering large areas and the operator can vary the angle of the beam without moving the probe. Applications include weld inspection, complex geometries, defect detection and location, and sizing. the ability to record weld scans and to visualize the reflectors and their position within the weld makes it a qualified technology and an excellent choice for projects constructed to All ASME phased array code cases , ASTM E2700-09 ASTM E2491-06, AWS, API 1104 and API RP2X,CEN EN 583-6

, BSI BS7706 And more

More NDT Services

Most Common NDT Methods

GPS providing Most Common NDT Methods ( PT, MT, UT, RT, VT ) as conventional NDt inspection,

Read more

Storage Tanks Inspection

oil and gas storage tank's life cycle can be managed with the computing solution, which enables the construction

Read more

Welding Inspection

Ultrasonic Testing of weld metals & other components, Ultrasonic Thickness gauging, Radiography Testing (X-

Read more

API Courses

• API 570 Authorized Piping Inspector preparation course • API 510 Authorized Pressure Vessel Inspector preparation course • API 653 Authorized Tank Inspector preparation course • API 577 Advanced Knowledge in Welding inspection & Metallurgy • API 571 Advanced Knowledge in Corrosion Damage mechanisms • API 580 Risk Based Inspection • API 579 Fitness for Service

Downloads

| 1-About GPS | About Gamma Petroleum Services |

| 2- GPS Rig Services | Rig Services |

| 3- GPS Advanced NDT | Advanced NDT Services |

| 4-Fluid Loss Control | Salt Pill Solutions & Fluid Loss Control |

| 5-Construction | Construction And Contracting |

| 6-Training | Training Services |

| 7-EX Services | Explosion Proof Ins. |

| 8-Drops Services | Dropped Object Surveys |

| 9-Calibration Services | Calibration & Testing |